Beat Supply Chain Gaps with These 5 Essential Answers

What’s a fleet manager to do? Container ships are stuck in port harbors, store shelves are laid bare, chip shortages are delaying production, 80,000 more truck drivers are needed and fuel prices are climbing. Getting connected lends cost-saving visibility to so many areas that supply chain challenges have impacted. When production on the ground is less reliable, you don’t want to be left wondering.

Many vehicles in the average fleet are likely already equipped with on-board telematics devices manufactured by the OEM. These devices track hoards of crucial information for your business and are activation-ready — the question is whether you’ve turned these vehicles on.

Check out five big questions this data can answer to see if these advanced insights can help your team make up for the supply chain delays of the past two years.

I ordered my vehicle. Where is it and when is it arriving?

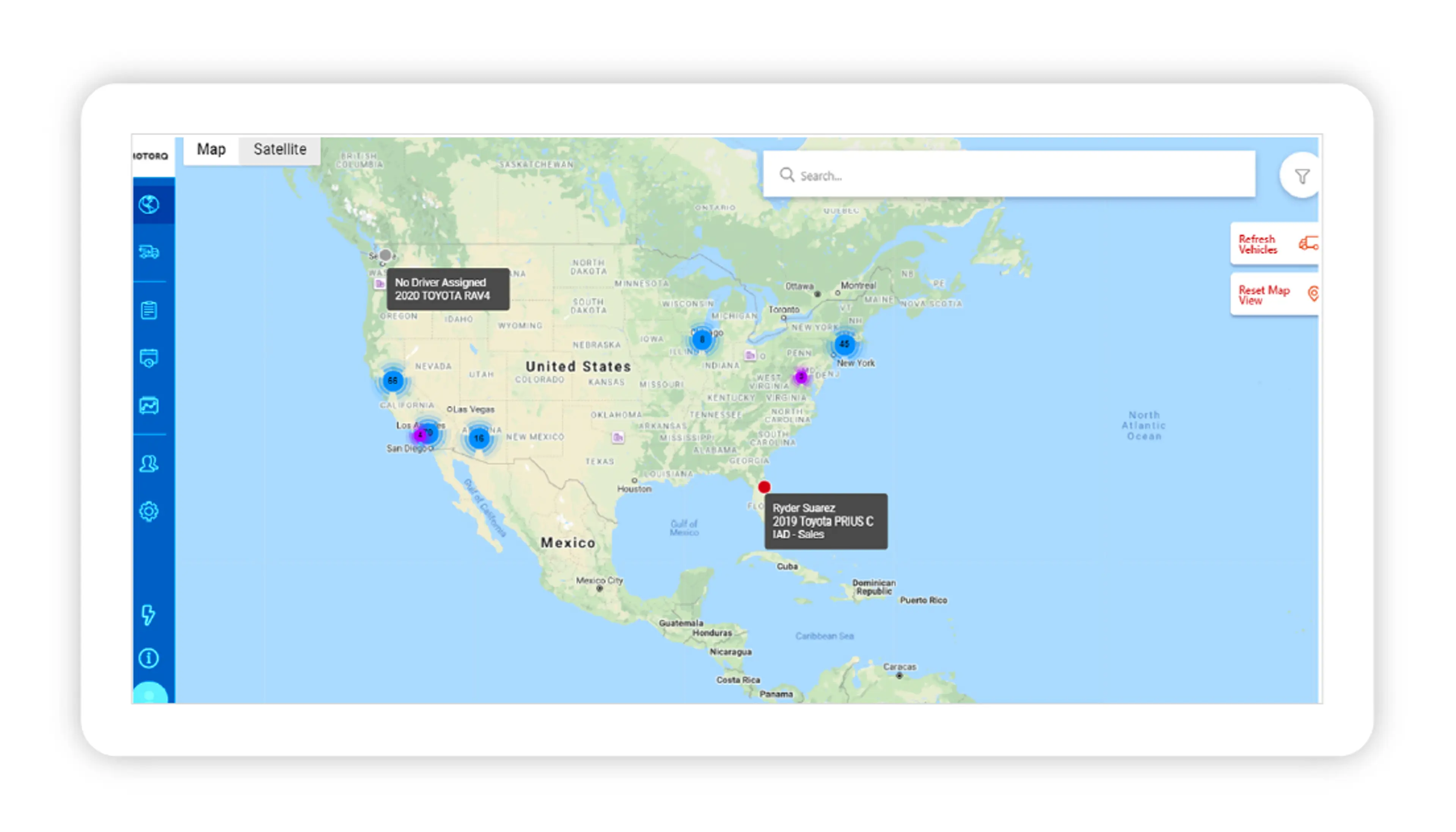

If you’re one of the lucky ones to be awaiting new vehicle delivery, you’ll want to be able to get that vehicle registered, plated and provisioned. The latest connected technology means you can track that vehicle’s progress from the factory floor to the dealer, ensuring maximum efficiency for in-fleeting.

Are your drivers going where they are supposed to (and are their route assignments optimal)?

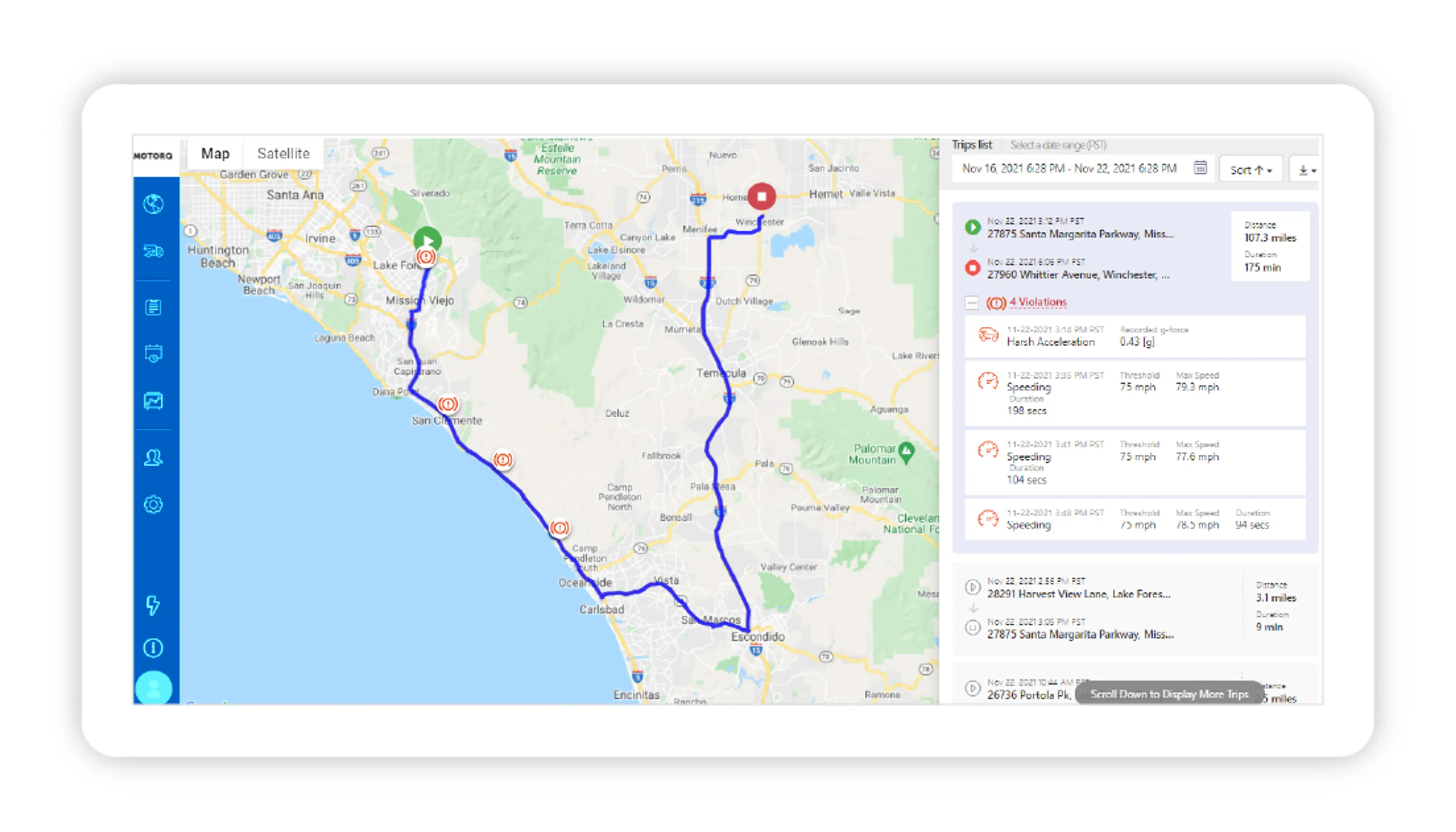

How efficient are their routes? With delays so rampant, you don’t want to guess where your drivers are or if they are meeting route efficiency standards. You can leverage on-board GPS and data streaming to paint accurate pictures of your vehicles and drivers.

Are my vehicles operating at peak capacity?

Can you afford to miss operating at peak capacity? And, even if you can, why would you want to? The secret, of course, is keeping vehicle downtime to a minimum. Connected cars tell you what they need – whether it’s air in a tire, an oil change or other maintenance issues. Similarly, you can track driver behavior to reduce unsafe driving habits, like hard braking/acceleration, speeding and seatbelt use. Safer driving means less risk for accidents and vehicle downtime.

How long will my EV battery last?

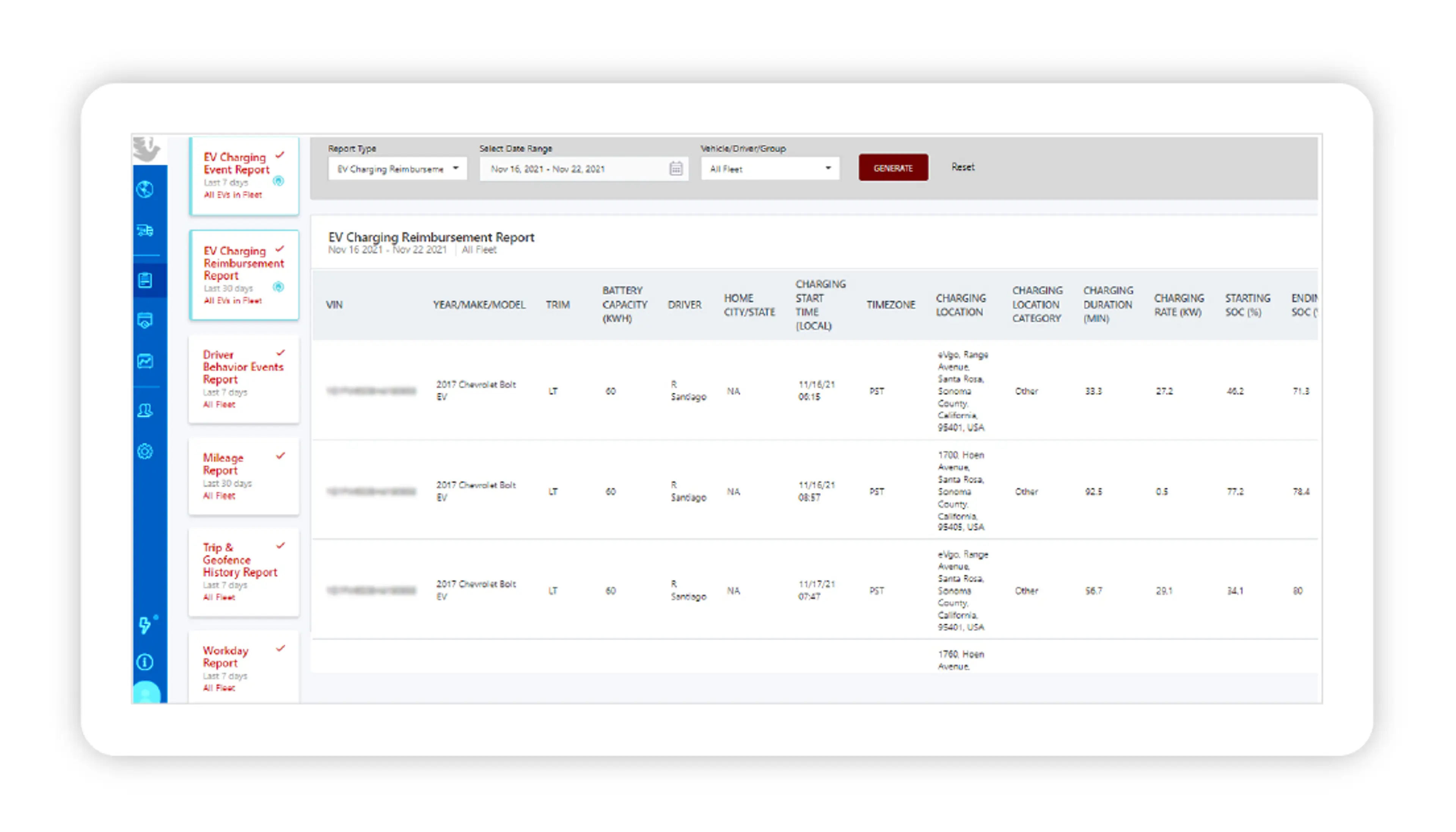

As you increase the number of EV’s in your fleet, you need to manage different criteria, like battery range, battery health and charging capability in order to get the most savings out of going fuel-free. Charting factors such as daily range vs. battery usage, battery efficiency vs. vehicle speed and battery efficiency vs. ambient temperature allows us to be able to determine the best range of your vehicle. We can then cross-reference that with charging locations, optimizing your distance, charging locations and your charge frequency, so you’ll get the most out of your battery. Our Machine Learning models have been able to predict battery failure within days of the actual event, and across of tens of thousands of batteries in a fleet.

Are my fuel cards being charged the right amounts, for the right vehicles?

With gas prices sky high, you can’t afford to spend money on fuel that’s not 100 percent used for your business. We are able to track both fuel card use as well as fuel tank level on a VIN and geolocation basis and produce “exception” reports – that is when more fuel is charged to a card than could have been filled in the tank. Over time, and fleet-wide, this can save you thousands of dollars.

These are just a few of the metrics that you can track, benchmark and improve through connected car data and analysis. And while all of them make sense in any business environment, they are all even more critical in today’s world where delays are costing businesses more than ever.